Dunkirk Metal Products Adds Advanced Tube Cutting Services

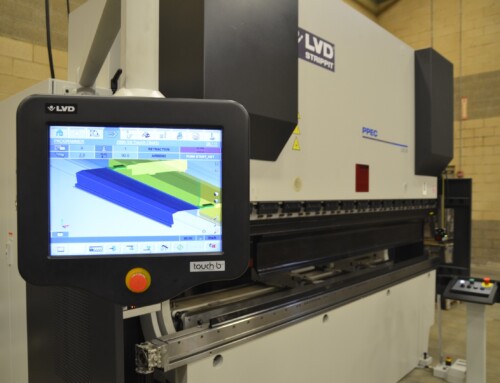

Dunkirk Metal Products proudly announces the addition of a new LVD Tube Laser cutting system. This investment expands our fabrication capabilities and supports our long-term manufacturing strategy.

We installed the tube laser in 2024. The system represents a major step toward becoming a true one-stop shop for metal parts and assemblies.

Supporting a One-Stop Manufacturing Approach

Dunkirk Metal Products continues to invest in equipment that expands in-house capabilities. Our goal is to reduce reliance on outside vendors while improving control over quality, cost, and lead times.

The tube laser plays a key role in this strategy. It allows us to process tube and structural components internally and integrate them directly into fabricated and welded assemblies.

By bringing tube laser cutting in-house, we simplify the supply chain. We also shorten production timelines and improve consistency across projects.

Precision Tube Cutting Services

The LVD tube laser delivers accurate and repeatable cuts. It processes a wide range of tubular and structural shapes with consistent results.

The system supports round, square, and rectangular tubing. It also cuts open profiles such as angle and C-channel. Each cut maintains clean edges and tight tolerances.

This cutting process reduces the need for secondary operations. In many cases, it eliminates drilling and milling entirely.

Improved Efficiency and Design Flexibility

Our engineers can now design complex cutouts, slots, holes, and notches that the system completes in a single operation.

High-powered fiber laser technology ensures accuracy on every part. Automated processing supports consistent quality from prototype to production.

Integrated Fabrication Solutions

Dunkirk Metal Products integrates tube laser cutting with forming, welding, machining, and assembly. This integration allows us to deliver complete metal assemblies from a single source.

Our team maintains quality control at every stage of production. Customers benefit from improved coordination and faster lead times.

Investing in the Future of Manufacturing

For more than 70 years, Dunkirk Metal Products has invested in modern equipment and skilled personnel. Each investment supports long-term growth and customer success.

The LVD Tube Laser strengthens our ability to deliver reliable, high-quality fabricated components. It also moves us closer to our goal of providing nearly any metal part or assembly under one roof.

To learn more about our tube laser cutting capabilities, contact our team today.

Leave A Comment