Key Factors in Evaluating Your Fabrication Supplier

Selecting the right fabrication supplier plays a critical role in product quality, delivery timelines, and overall manufacturing efficiency. Whether you are sourcing custom metal components, assemblies, or full production runs, the supplier you choose should do more than simply fulfill orders.

A high-quality fabrication supplier brings technical expertise, reliable processes, and a collaborative approach that supports your business long term. Below are the key factors to consider when evaluating a fabrication supplier.

Wide Capabilities Are Essential

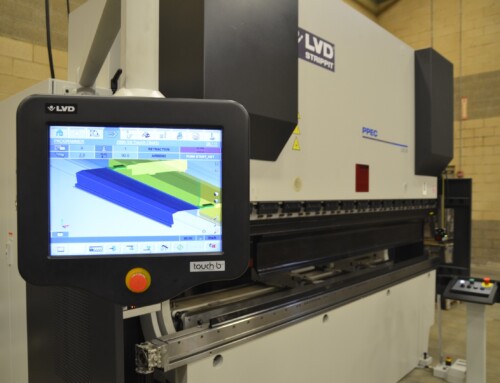

One of the first things to look for in a fabrication supplier is the ability to handle multiple processes in-house. A supplier with broad capabilities can manage projects more efficiently and maintain tighter quality control.

A capable fabrication supplier should offer:

- Laser cutting for sheet and tube

- Forming and bending

- Welding and mechanical assembly

- Machining or secondary operations

- Prototyping through full production

Having these services under one roof reduces lead times, minimizes coordination issues, and ensures consistent results from start to finish.

Quality Systems Separate a Reliable Fabrication Supplier from the Rest

Quality should be built into every step of the manufacturing process. A dependable fabrication supplier will have documented quality systems that ensure repeatability and accountability.

Key quality indicators include:

- Material traceability

- In-process and final inspections

- Calibrated equipment and tooling

- Corrective action procedures

- Continuous improvement practices

These systems help prevent defects, reduce rework, and provide confidence that your parts meet specifications every time.

Geographic Location Matters

Working with a geographically convenient fabrication supplier offers real operational advantages. Shorter shipping distances translate to faster delivery, lower freight costs, and better responsiveness.

Benefits of a regional fabrication supplier include:

- Faster turnaround times

- Easier facility visits and audits

- Improved communication

- Reduced supply chain risk

For companies in the Northeast and Great Lakes region, partnering with a nearby fabrication supplier can significantly improve reliability and flexibility.

Experienced Engineers Add Value Beyond the Quote

An experienced fabricator brings engineering insight that improves both design and manufacturability. Rather than simply producing what’s on the drawing, the right supplier helps optimize parts before production begins.

Engineering support may include:

- Design for manufacturability (DFM)

- Material selection guidance

- Cost-reduction recommendations

- Tolerance and process optimization

This collaborative approach leads to better parts, fewer production issues, and lower total costs over the life of a program.

The Best Suppliers as a Manufacturing Partner

The most valuable fabrication supplier is one that operates as a partner, not an order taker. This mindset leads to stronger communication, proactive problem-solving, and long-term success.

A partner-focused fabrication supplier will:

- Ask questions to fully understand your application

- Identify potential issues early

- Communicate clearly and consistently

- Support both short-term needs and future growth

When challenges arise, a true partner works with you to find solutions rather than simply fulfilling the minimum requirement.

Choosing the Right Partner Long-Term Success

Selecting a fabrication supplier is about performance, reliability, and collaboration. A supplier with wide capabilities, strong quality systems, convenient location, experienced engineers, and a partnership mindset will deliver greater value over time.

At Dunkirk Metal Products, we approach every project as a long-term partnership, delivering high-quality fabricated components backed by engineering support and dependable processes. Contact us and see the difference!

Leave A Comment