Your Products Ship Sooner With An Efficient Fabricator

Choosing the right metal fabricator has a direct impact on your production timelines and total manufacturing costs. Beyond cutting and forming metal, a capable fabricator plays a strategic role in supply chain efficiency, inventory planning, and cost control.

By combining operational flexibility with engineering insight and strong supplier relationships, a metal fabricator can help customers stay competitive in demanding markets. Below are the key ways a metal fabricator helps reduce lead times and costs.

Blanket Orders and Forecasting Improve Production Efficiency

One of the most effective ways a metal fabricator reduces lead times is through blanket orders and long-term forecasting. Rather than reacting to individual purchase orders, a fabricator can plan production around expected demand.

Benefits of blanket orders include:

- Locked-in material pricing

- Reduced setup and changeover time

- More predictable production scheduling

- Faster release of finished parts

By aligning forecasts with production planning, a metal fabricator can respond quickly when releases are needed without restarting the entire process each time.

Pre-Working Partials Speeds Final Delivery

An experienced metal fabricator understands which operations can be completed ahead of time. By pre-working partial components such as cutting, forming, or sub-assembly, fabricators can dramatically shorten final lead times.

This approach allows:

- Faster turnaround upon receipt of a release order

- Better use of shop capacity during slower periods

- Reduced bottlenecks during peak demand

When the final order is released, only finishing operations remain, allowing parts to ship quickly and reliably.

In-House Delivery Reduces Freight Costs and Delays

Logistics is often an overlooked cost driver. A metal fabricator with its own delivery trucks can eliminate many of the expenses and uncertainties associated with third-party freight carriers.

Advantages of in-house delivery include:

- Lower shipping costs

- Reduced risk of freight damage

- More predictable delivery schedules

- Faster response to urgent needs

For regional customers, direct delivery from the metal fabricator often results in both cost savings and improved service reliability.

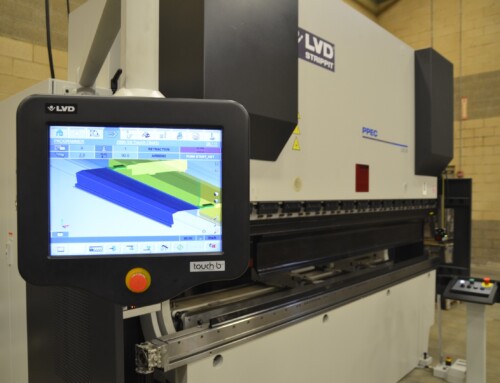

Smarter Design Reduces Manufacturing Inefficiencies

The right metal fabricator doesn’t just build parts—they help design them more efficiently. Engineering expertise allows fabricators to identify opportunities to reduce unnecessary complexity, tight tolerances, or inefficient features.

Smarter design can lead to:

- Fewer manufacturing steps

- Shorter cycle times

- Less material waste

- Lower overall part costs

Design for manufacturability (DFM) collaboration early in the process prevents costly changes later and ensures parts are optimized for production from the start.

Strong Material Supplier Relationships Improve Speed and Pricing

A dependable partner maintains a strong, diverse material supplier base. These relationships help secure better pricing, faster material availability, and consistent quality.

A strong supplier network enables:

- Shorter material lead times

- Reduced risk of shortages

- Access to alternative materials when needed

- More stable pricing during market fluctuations

This supply chain strength allows a metal fabricator to keep projects moving even when material markets are tight.

Why the Right Metal Fabricator Makes a Measurable Difference

In addition to efficient machines, reducing lead times also requires planning, experience, and collaboration. A capable fabrication supplier uses forecasting, partial processing, in-house logistics, engineering support, and supplier relationships to create measurable advantages for customers.

At Dunkirk Metal Products, we work closely with customers to reduce lead times, control costs, and build reliable manufacturing partnerships that scale with demand. Contact us to get started!

Leave A Comment